Industry Pain Points

Focus on industry pain points, targeted to solve the needs of enterprises

Supply chain upstream and downstream fragmentation

The manufacturing industry and upstream and downstream suppliers and customers are not coordinated enough, and visualization is not strong, including procurement and logistics coordination, cost settlement, inventory sharing, and so on.

Complex materials require accurate delivery

The variety of parts is complex, which requires fast warehousing, accurate distribution and elimination of material shortage. When facing order production, complete distribution and fast online are required. The production rhythm is unstable, and distribution is required to be pulled according to production consumption.

manufacturing cost pressure

The large inventory of materials and finished products requires accurate inventory, high efficiency of logistics operations, accelerated material turnover, compressed inventory and reduced costs.

Transportation system is not efficient

Manufacturers need efficient transportation systems to ensure that parts are delivered to the factory on time and finished products are delivered to customers/distributors on time. Inefficient and opaque transport systems are adversely affected.

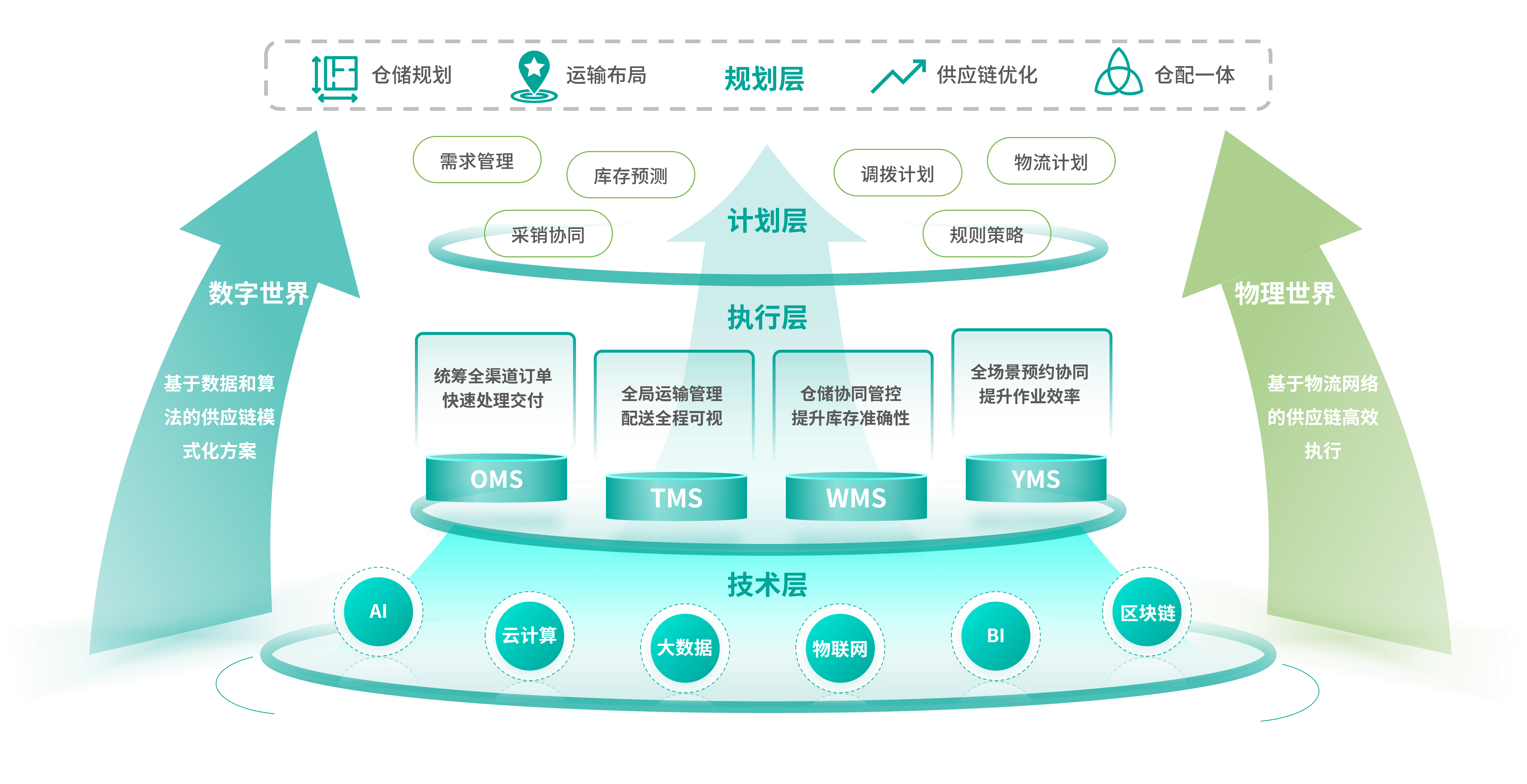

Deep Insights Intelligent Manufacturing Solution

Co-creation with advanced enterprises, both industry versatility and personalization.

Value to Customers

Comprehensive digital management of processes, enabling enterprises to improve quality and efficiency.

“

Reduced number of workers and complaint rate

- Increased efficiency of transportation and warehousing operations

- and upstream and downstream operations to improve efficiency

- Inventory accuracy is improved on the original basis.

- Increased utilization of warehouse space

“

Data accuracy

- Inventory data accuracy

- Real-time accuracy of cross-system data such as ERP, MES, WMS and TMS

- KPI and report data are accurate and visible in real time

“

Reduced number of workers and complaint rate

- Decreased number of personnel for order processing, warehousing and transportation operations

- Decreased material shortage rate in the production process

- Dealer/Customer Complaint Rate Decreased

Why Choose Us?

Innovative supply chain products with both functions and services

Full end-to-end business coverage

- Plan-Purchase-Transport-Distribution-Production-Delivery

- Full coverage of different business types such as mass production and customization.

- Suppliers, customers, logistics companies in logistics, financial business coverage

- Meet different forms of order management, warehousing, transportation, and production pull business scenarios.

full integration of information flow business

- Open up the isolated island of information and realize the comprehensive, efficient and safe flow and sharing of information.

- Integrate and integrate the information systems of internal business units and external supply chain partners.

- Unified information platform to improve the operational efficiency and decision-making ability of enterprises

Process optimization and integration

- Optimize different business processes within the manufacturing industry to improve process efficiency, reduce resource waste, reduce costs, and improve quality

- Optimize and integrate external business processes by combining the upstream and downstream external environment of the supply chain

- Optimized process monitoring and evaluation to improve processes in a timely manner

The evaluation of Dongyin is that the delivery ability is the strongest.

Operation standardization

- Establish standardization of different business operations to ensure efficient operation of processes

- Standardize operations to form standardized supply chain operations through programs and systems

- Operation data standardization, all kinds of data unified specification, to ensure data accuracy and reliability

Customer Cases

Practical in the field of supply chain digitalization, customer success-oriented practitioner

Products

Products Solution

Solution Resource

Resource About Us

About Us